Brewery waste can be repurposed to make nanoparticles that can fight bacteria

- Written by Alcina Johnson Sudagar, Research Scientist in Chemistry, Washington University in St. Louis

Modern beer production is a US$117 billion business[1] in the United States, with brewers producing over 170 million barrels[2] of beer per year. The brewing process is time- and energy-intensive[3], and each step generates large amounts of waste.

Solid components such as used grains and yeast from this waste end up in landfills, where harmful compounds can leach into the soil[4]. Brewing wastewater that makes it into aquatic ecosystems can contaminate streams and lakes, decrease oxygen levels[5] in those environments and threaten organisms.

To keep this waste from going into the environment, scientists like me are exploring how to manufacture beer brewing waste into useful products. I’m a chemist[6], and my research team and I are interested in figuring out how to recycle and repurpose brewery waste into tiny particles that can be used to make new types of prescription drugs.

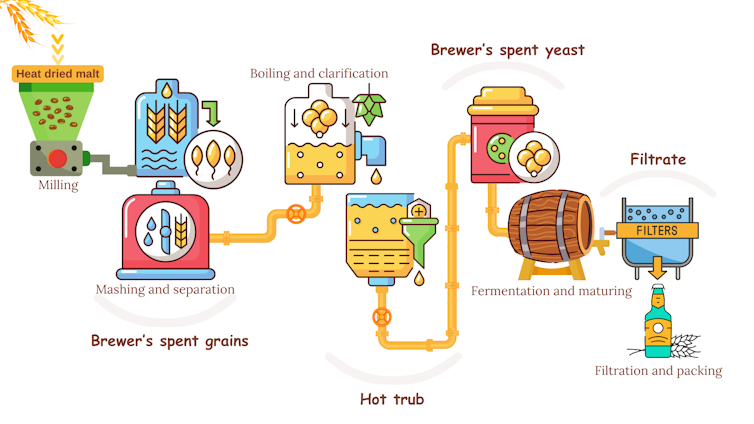

The brewing process

The brewing process[7] takes raw cereal grain – usually from barley – and converts its starch and proteins into simpler chemicals by malting[8]. Brewers initiate this process by adding water, which wakes the seed from dormancy, and then keeping the seeds at a controlled temperature to sprout the grain.

During this time, important enzymes are released that can convert the starch and proteins in the grains to fermentable sugars and amino acids[9]. They then heat up the resulting product, called the malt, to dry it out and stop further sprouting. After this malting process, they add hot water and mash the malt to release the compounds that give the beer its iconic flavor.

The brewers then separate the sweet malt extract, called wort[11], and the leftover solid is removed as waste, called brewer’s spent grains. About 30% of the weight[12] of the raw grain ends up as spent grain waste. This waste is either used as animal feed or discarded. About 30 million tons of spent grain[13] is generated annually.

Brewers add a cone-shaped flower of the Humulus lupulus plant, called hops[14], to the wort, then boil and clarify it. The hops flower is the key ingredient that gives beer its bitterness and aroma. The undissolved hops and proteins get collected during clarification to form hot trub, the second major waste from breweries. Roughly 85% of the hops[15] are removed as waste material.

The clear wort is then cooled and fermented by adding yeast. The yeast filtered out after fermentation, called brewer’s spent yeast, forms the third type of waste that breweries generate. The spent yeast is one of the major byproducts of the brewing industry. This waste has a large quantity of water and solid material: 100 liters of beer generate 2 to 4 kilograms (4.4 to 8.8 lbs.) of spent yeast[16].

Finally, the fermented beer is filtered before entering the production line, where the beer is bottled for consumption. The wastewater generated at this last stage forms the filtration waste. A medium-size brewery generates about 8 tons of dense sludge and five to seven times – or 40 to 56 tons – of wastewater as filtration waste monthly[17]. Several tons of waste from breweries remain largely underused due to their low economic value.

The brewery waste problem

These wastes have several compounds[18], such as carbohydrates, proteins, amino acids, minerals and vitamins that can potentially be repurposed. Scientists have tried to reuse the wastes in creative ways by creating biofuels[19] and vegan leather[20] using either some compounds extracted from the waste or the entire waste.

Breweries can send their solid wastes to farms that repurpose it as soil fertilizer[21], compost[22] or animal feed[23], but a major fraction of it industrywide is discarded as landfill. The wastewater is discharged into the sewage lines, which can challenge sewage treatment systems, as they contain more than 30 times higher pollutants[24] than the typical residential sewage.

Although breweries are becoming more aware of their waste and moving toward sustainable approaches, demand for beer has continued to rise, and a large amount of waste remains to be dealt with.

Repurposing waste in nanoparticles

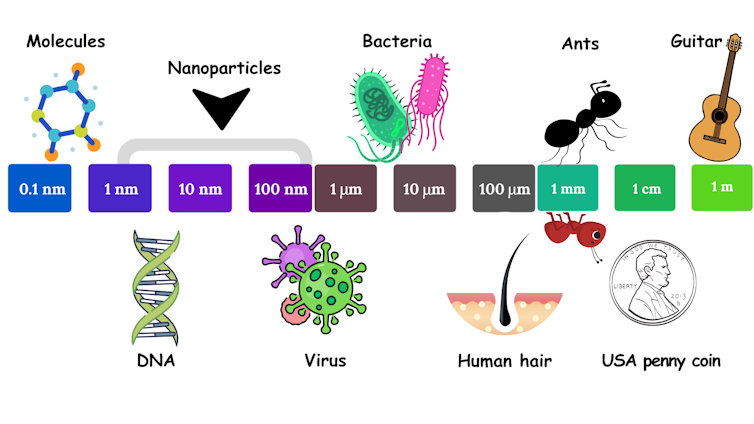

In my research, I’m interested in determining whether compounds from brewery waste can help create nanoparticles[25] that are compatible with human cells but fight against bacteria. Nanoparticles are extremely tiny particles[26] that have sizes in the range of one-billionth of a meter.

In medicine, when the same antibiotics are used over and over, bacteria can evolve resistance against them[28]. One potential use of nanoparticles is as an active component in certain antibiotic drugs. These nanoparticles could also work as disinfectants and cleaning chemicals[29].

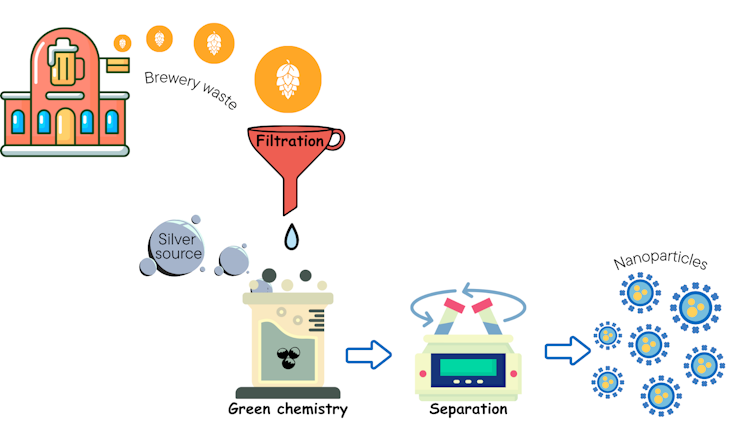

My team and I developed nanoparticles coated with some of the compounds found in brewery waste – an invention which we have since patented[30] but are not actively commercializing. We created the particles by adding waste from any stage of brewing to a metal source.

When we added a chemical containing silver – for example, silver nitrate[31] – to the waste, a combination of processes converted silver compound into nanoparticles. One process is called reduction[32]: Here, compounds found in the brewery waste undergo a chemical reaction that converts the silver ions from the silver nitrate to a metallic nanoparticle.

The other process, called precipitation[33], is similar to how chalky soap scum forms in your sink when soap reacts with minerals such as calcium in hard water. Oxide and phosphate from the brewery waste combine with a silver ion from the silver nitrate, causing the silver to form a solid compound that makes up the nanoparticle’s core.

The organic compounds from the brewing waste[34] such as proteins, carbohydrates, polyphenols and sugars form a coating on the nanoparticles. This coating prevents any other reaction from happening on the surface of these particles, which is very important for making the nanoparticles stable for their applications. These nanoparticles prepared from brewery waste were made of three components: silver metal, silver oxide and silver phosphate[35].

Environmentally friendly processes that reduce the use of hazardous chemicals and minimize harmful side products are known as green chemistry[37]. Because our procedure was so simple and did not use any other chemicals, it falls into this green chemistry category.

Nanoparticle safety

My colleague Neha Rangam[38] found that the coating formed by the brewery waste compounds makes these nanoparticles nontoxic[39] to human cells in the lab. However, the silver from these nanoparticles killed Escherichia coli[40], a common bacterium responsible for intestinal illness around the world.

We found that a special type of nanoparticle containing high amounts of silver phosphate worked against E. coli. It appeared that this silver phosphate nanoparticle had a thinner coating of the organic compounds from the brewery waste than silver metal and oxides, which led to better contact with the bacteria. That meant enough silver could reach the bacteria to disrupt its cellular structure. Silver has long been known to have an antimicrobial effect[41]. By creating nanoparticles from silver, we get lots of surface area available for eliminating bacteria.

Several nanoparticles have been in clinical trials[42] and some have been FDA approved for use in drugs[43] for pain management, dental treatment and diseases such as cancer and COVID-19. Most research into nanoparticles in biotechnology has dealt with carbon-based[44] nanoparticles. Scientists still need to see how these metal nanoparticles would interact with the human body and whether they could potentially cause other health problems.

Because they’re so tiny, these particles are difficult to remove from the body unless they are attached to drug carriers designed to transport the nanoparticles safely. Before doctors can use these nanoparticles as antibacterial drugs, scientists will need to study the fate of these materials once they enter the body.

Some engineered nanoparticles can be toxic[45] to living organisms, so research will need to address whether these brewery waste-derived nanoparticles are safe for the human body before they’re used as a new antibacterial drug component.

References

- ^ beer production is a US$117 billion business (www.brewersassociation.org)

- ^ 170 million barrels (www.brewersassociation.org)

- ^ time- and energy-intensive (doi.org)

- ^ leach into the soil (doi.org)

- ^ decrease oxygen levels (doi.org)

- ^ I’m a chemist (scholar.google.com)

- ^ The brewing process (www.brewersassociation.org)

- ^ by malting (www.sciencedirect.com)

- ^ fermentable sugars and amino acids (www.britannica.com)

- ^ CC BY-SA (creativecommons.org)

- ^ called wort (www.beerandbrewing.com)

- ^ 30% of the weight (doi.org)

- ^ 30 million tons of spent grain (doi.org)

- ^ called hops (cropsandsoils.extension.wisc.edu)

- ^ 85% of the hops (doi.org)

- ^ 100 liters of beer generate 2 to 4 kilograms (4.4 to 8.8 lbs.) of spent yeast (doi.org)

- ^ filtration waste monthly (doi.org)

- ^ have several compounds (doi.org)

- ^ creating biofuels (doi.org)

- ^ vegan leather (www.shanferments.com)

- ^ soil fertilizer (doi.org)

- ^ compost (doi.org)

- ^ animal feed (www.hobbyfarms.com)

- ^ 30 times higher pollutants (aquacycl.com)

- ^ nanoparticles (doi.org)

- ^ Nanoparticles are extremely tiny particles (theconversation.com)

- ^ CC BY-SA (creativecommons.org)

- ^ bacteria can evolve resistance against them (www.who.int)

- ^ disinfectants and cleaning chemicals (doi.org)

- ^ we have since patented (ewyszukiwarka.pue.uprp.gov.pl)

- ^ silver nitrate (pubchem.ncbi.nlm.nih.gov)

- ^ process is called reduction (chem.libretexts.org)

- ^ called precipitation (www.labxchange.org)

- ^ organic compounds from the brewing waste (doi.org)

- ^ silver metal, silver oxide and silver phosphate (doi.org)

- ^ CC BY-SA (creativecommons.org)

- ^ green chemistry (www.epa.gov)

- ^ Neha Rangam (scholar.google.com)

- ^ nanoparticles nontoxic (ichf.edu.pl)

- ^ killed Escherichia coli (www.mdpi.com)

- ^ antimicrobial effect (doi.org)

- ^ clinical trials (doi.org)

- ^ FDA approved for use in drugs (jnanobiotechnology.biomedcentral.com)

- ^ carbon-based (jnanobiotechnology.biomedcentral.com)

- ^ Some engineered nanoparticles can be toxic (pubs.acs.org)

Authors: Alcina Johnson Sudagar, Research Scientist in Chemistry, Washington University in St. Louis