Squid have tiny teeth in their suckers − scientists could use their unique properties to make self-healing materials

- Written by Abdon Pena-Francesch, Assistant Professor of Materials Science and Engineering, University of Michigan

When you think of a fearsome, sharp-toothed predator, a squid probably isn’t the first animal that comes to mind. But these complex creatures have sophisticated eyesight[1], a strong beak to crush shells[2] and agile tentacles that help them snatch up prey.

Oh, and they have teeth in their suckers. The serrated teeth inside the suction cups on their tentacles[3] allow them to latch onto prey.

While most hard tissues in animals are mineralized, with calcium fortifying their bones, shells or teeth, the squids’ sucker teeth are instead composed of structural proteins. Scientists don’t really understand how these teeth are made.

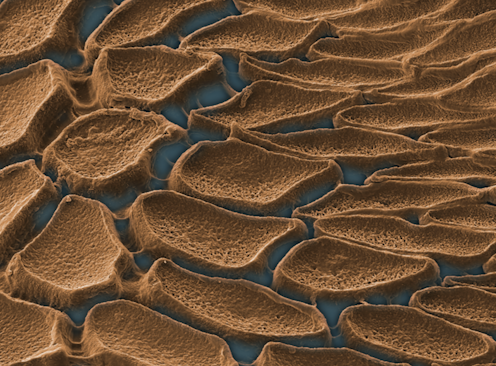

By looking inside a squid sucker using an electron microscope, our team of scientists[4] captured an image that shows the cell tissue that grows the teeth. The cells located in the inside walls of the suction cup secrete proteins that bind to each other and form complex teethed-ring structures.

High-strength proteins in squid sucker teeth

Squid sucker teeth have some outstanding properties. They’re resistant to compression, yet they’re flexible and can conform to the shape of their prey. Our team’s research tries to understand not only how these teeth are made, but also where their unique properties come from.

The teeth are composed of a family of structural proteins[5], which have a mechanical function rather than a biological function. Some examples include keratin, which makes up hair and nails, or silk, which gives structure to spider webs and silkworm cocoons. In squids, these sucker teeth catch and grip onto prey.

Proteins are made of amino acids arranged in a specific order, and that order defines their structure. Sucker teeth proteins have amino acids that form hard, tiny crystals called nanocrystals in the material. These nanocrystals connect the protein strands in a network – similar to knots in a fishing net.

These nanocrystals come together to form nanotubes inside the material, like tiny honeycomb structures. When we look at them through an electron microscope, we can see a tooth cut in half, revealing the intricate internal structure with long but tiny nanotubes. Thanks to these nanostructures, the squid protein teeth have strength, toughness and a flexibility that outperforms many synthetic polymers and modern materials.

Squid-inspired new materials

Scientists and engineers can take inspiration from biology[6] and use unique natural structures to model and develop new types of materials. For example, squid sucker ring teeth have inspired the development of self-healing materials[7] that can repair their own cuts, punctures or scratches.

The nanocrystals that hold together the squid teeth proteins can reform after they break. Materials made in our lab inspired by squid nanocrystals could lead to self-repairing medical devices or robots[8]. These materials would last longer and require less upkeep, which would be useful in dangerous environments or inside the human body.

These squid-inspired materials could also assemble and disassemble by themselves. Materials with this property could be recycled or degraded[9] without leaving behind any waste. That would make this sort of material a promising bio-based alternative to single-use plastic[10].

References

- ^ have sophisticated eyesight (www.sciencefriday.com)

- ^ a strong beak to crush shells (www.nationalgeographic.com)

- ^ serrated teeth inside the suction cups on their tentacles (www.tepapa.govt.nz)

- ^ our team of scientists (www.apenafrancesch.com)

- ^ structural proteins (doi.org)

- ^ take inspiration from biology (theconversation.com)

- ^ self-healing materials (doi.org)

- ^ self-repairing medical devices or robots (doi.org)

- ^ recycled or degraded (www.frontiersin.org)

- ^ single-use plastic (theconversation.com)

Authors: Abdon Pena-Francesch, Assistant Professor of Materials Science and Engineering, University of Michigan