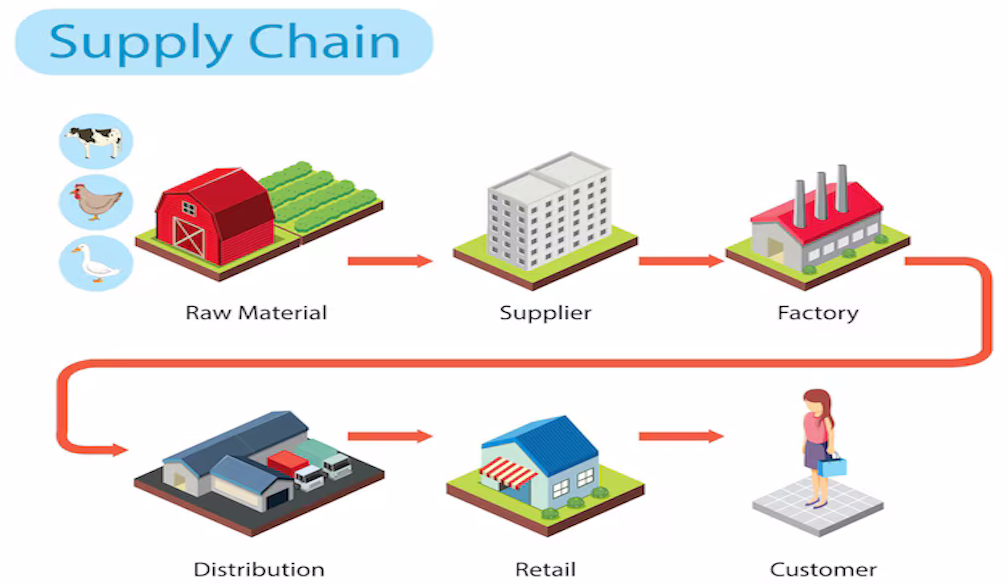

How Asset Tracking is Transforming Supply Chain Management in Australia

The Challenges Faced in Supply Chain Management in Australia

Supply chain management in Australia has always been a complex and multifaceted challenge. The country's vast geographical size, remote locations, and diverse industries have created unique obstacles that businesses must overcome. One of the primary challenges is the difficulty in maintaining visibility and control over assets throughout the supply chain.

Traditionally, companies have relied on manual processes and outdated systems to track their assets, leading to a lack of real-time information and increased risks of loss, theft, or misplacement. This lack of visibility can have a significant impact on operational efficiency, customer satisfaction, and overall profitability. Additionally, the complex regulatory environment and stringent compliance requirements in Australia add an extra layer of complexity to supply chain management.

Another key challenge is the ability to respond quickly to changing market conditions and customer demands. With the rise of e-commerce and the increasing expectations of consumers, Australian businesses must be agile and adaptable to remain competitive. This requires a deep understanding of their supply chain operations and the ability to make data-driven decisions to optimise their processes.

The Role of Asset Tracking in Addressing Supply Chain Challenges

In the face of these challenges, asset tracking has emerged as a transformative solution for supply chain management in Australia. By leveraging advanced technologies such as Radio Frequency Identification (RFID), Global Positioning System (GPS), and the Internet of Things (IoT), businesses can now gain unprecedented visibility and control over their assets throughout the entire supply chain.

Asset tracking systems provide real-time data on the location, condition, and utilisation of assets, allowing companies to make informed decisions and optimise their operations. This visibility can help organisations reduce the risk of lost or stolen assets, improve inventory management, and enhance overall supply chain efficiency.

Furthermore, asset tracking solutions can help companies respond more quickly to changing market conditions and customer demands. By providing real-time data on asset availability and performance, businesses can make agile decisions, adapt their processes, and deliver products or services more effectively. This can lead to improved customer satisfaction, increased revenue, and a competitive advantage in the Australian market.

Types of Asset Tracking Technologies Used in Supply Chain Management

The adoption of asset tracking technologies in supply chain management in Australia has been steadily increasing, with a range of solutions available to suit the diverse needs of businesses. Some of the most commonly used asset tracking technologies include:

- Radio Frequency Identification (RFID): RFID technology uses radio waves to wirelessly identify, categorise, and track assets. RFID tags attached to assets can be detected by RFID readers, providing real-time data on the location and status of the assets.

- Global Positioning System (GPS): GPS-based asset tracking solutions use satellite technology to provide accurate location data for assets, particularly during transportation and logistics operations.

- Bluetooth Low Energy (BLE): BLE-based asset tracking systems use small, battery-powered beacons to transmit signals that can be detected by nearby devices, allowing for the tracking of assets within a specific range.

- Internet of Things (IoT): IoT-enabled asset tracking solutions integrate various sensors and connectivity technologies to provide comprehensive data on the condition, utilisation, and performance of assets throughout the supply chain.

- Barcode and QR Code Scanning: Traditional barcode and QR code scanning technologies are also used in asset tracking, providing a cost-effective way to identify and manage assets.

Each of these technologies has its own strengths and weaknesses, and businesses in Australia must carefully evaluate their specific requirements to choose the most suitable asset tracking solution for their supply chain operations.

Benefits of Implementing Asset Tracking in Supply Chain Management

The implementation of asset tracking solutions in supply chain management in Australia has led to a wide range of benefits for businesses, including:

- Improved Visibility and Control: Asset tracking provides real-time visibility into the location, condition, and utilisation of assets, allowing companies to make informed decisions and optimise their operations.

- Enhanced Inventory Management: By tracking the movement and status of assets, businesses can better manage their inventory, reduce the risk of stockouts, and improve order fulfillment.

- Reduced Costs: Asset tracking can help companies identify and address inefficiencies, reduce the risk of lost or stolen assets, and optimise the use of their resources, leading to significant cost savings.

- Increased Operational Efficiency: With the ability to monitor asset performance and utilisation, businesses can streamline their processes, reduce downtime, and improve overall productivity.

- Improved Supply Chain Resilience: Asset tracking can help companies better anticipate and respond to supply chain disruptions, mitigating the impact on their operations and customer satisfaction.

- Enhanced Regulatory Compliance: Asset tracking solutions can assist businesses in meeting various regulatory requirements, such as asset management, maintenance, and reporting.

- Improved Customer Satisfaction: By optimising their supply chain operations, companies can deliver products and services more efficiently, leading to higher customer satisfaction and loyalty.

These benefits have made asset tracking a crucial component of supply chain management in Australia, as businesses strive to stay competitive and meet the evolving demands of the market.

Considerations for Choosing the Right Asset Tracking Solution for Your Business

When it comes to implementing asset tracking in your supply chain management, it's crucial to select the right solution that aligns with your specific business needs and requirements. Here are some key considerations to keep in mind:

- Scalability and Flexibility: Choose a solution that can accommodate your current and future asset tracking requirements, allowing for easy scalability as your business grows.

- Integration Capabilities: Ensure the asset tracking system can seamlessly integrate with your existing enterprise resource planning (ERP) systems, warehouse management systems, and other critical business applications.

- Data Accuracy and Reliability: Evaluate the accuracy and reliability of the asset tracking data provided by the solution, as this will directly impact the quality of your decision-making.

- Ease of Implementation and Use: Consider the complexity of implementation and the user-friendliness of the asset tracking system, as this will affect the adoption and utilisation by your employees.

- Cost-Effectiveness: Assess the total cost of ownership, including hardware, software, maintenance, and training, to ensure the solution aligns with your budget and delivers a positive return on investment.

- Security and Data Privacy: Ensure the asset tracking solution adheres to the appropriate data security and privacy standards, particularly if you're handling sensitive information or operating in a regulated industry.

- Ongoing Support and Maintenance: Evaluate the level of support and maintenance provided by the solution provider, as this will be crucial for the long-term success of your asset tracking implementation.

By carefully considering these factors, you can select the most suitable asset tracking solution for your supply chain management in Australia, ensuring a seamless and effective implementation that delivers tangible business benefits.

Implementing Asset Tracking in Your Supply Chain Management: A Step-by-Step Guide

Implementing an asset tracking solution in your supply chain management can be a complex process, but by following a structured approach, you can ensure a successful deployment. Here's a step-by-step guide to help you get started:

- Assess Your Current Situation: Conduct a thorough analysis of your existing supply chain management practices, identify the pain points and challenges, and determine the specific objectives you want to achieve through asset tracking.

- Define Your Requirements: Based on your assessment, clearly define the requirements for your asset tracking solution, including the types of assets to be tracked, the data you need to collect, the desired level of visibility, and the integration requirements with your existing systems.

- Evaluate and Select the Right Solution: Research and evaluate various asset tracking solutions available in the market, considering the factors outlined in the previous section. Engage with solution providers, request demonstrations, and conduct a cost-benefit analysis to determine the best fit for your business.

- Plan the Implementation: Develop a detailed implementation plan, including timelines, resource requirements, training needs, and a change management strategy to ensure a smooth transition for your organisation.

- Deploy the Solution: Work closely with your selected solution provider to deploy the asset tracking system, ensuring proper installation, configuration, and integration with your existing systems.

- Train and Educate Your Team: Provide comprehensive training to your employees on the use and benefits of the asset tracking solution, empowering them to leverage the system effectively.

- Monitor and Optimise: Continuously monitor the performance of your asset tracking system, analyse the data, and make adjustments to optimise your supply chain management processes over time.

- Measure and Evaluate: Establish key performance indicators (KPIs) to measure the success of your asset tracking implementation, and regularly evaluate the tangible benefits and return on investment.

By following this step-by-step approach, you can ensure a successful implementation of an asset tracking solution in your supply chain management, unlocking the full potential of this transformative technology in the Australian market.

Future Trends and Innovations in Asset Tracking for Supply Chain Management

As the supply chain landscape in Australia continues to evolve, the role of asset tracking is expected to become even more crucial. Here are some of the key trends and innovations that will shape the future of asset tracking in supply chain management:

- Increased Adoption of IoT and Sensor Technology: The growing prevalence of IoT devices and advanced sensors will enable more comprehensive and real-time data collection on the condition, performance, and utilisation of assets throughout the supply chain.

- Advancements in Predictive Analytics: Leveraging machine learning and artificial intelligence, asset tracking solutions will provide predictive insights to help businesses anticipate and respond to potential supply chain disruptions, optimise asset maintenance, and improve overall operational efficiency.

- Blockchain Integration: The integration of blockchain technology with asset tracking systems will enhance data security, transparency, and traceability, making it easier for businesses to verify the provenance and authenticity of their assets.

- Autonomous and Robotic Asset Tracking: The integration of autonomous vehicles, drones, and robotics with asset tracking solutions will enable more efficient and precise monitoring and management of assets, particularly in warehousing and logistics operations.

- Augmented Reality and Visualisation: The use of augmented reality (AR) and advanced data visualisation tools will provide supply chain managers with more intuitive and interactive ways to monitor and manage their assets, improving decision-making and collaboration.

- Sustainability and Environmental Impact: As sustainability becomes a growing concern, asset tracking solutions will increasingly focus on monitoring and optimising the environmental impact of supply chain operations, such as energy consumption, emissions, and waste management.

- Increased Collaboration and Data Sharing: The rise of supply chain ecosystems and collaborative platforms will enable businesses to share asset tracking data and insights, fostering greater transparency, risk mitigation, and overall supply chain resilience.

These trends and innovations will continue to shape the future of asset tracking in supply chain management in Australia, empowering businesses to stay ahead of the curve and maintain a competitive edge in the ever-evolving market.

Conclusion: The Impact of Asset Tracking on Supply Chain Management in Australia

The transformative impact of asset tracking on supply chain management in Australia cannot be overstated. By providing real-time visibility, enhanced control, and data-driven insights, asset tracking solutions have become a crucial component of modern supply chain operations.

As Australian businesses navigate the complexities of the supply chain landscape, the adoption of asset tracking technologies has enabled them to overcome challenges, optimise their processes, and deliver superior customer experiences. From improved inventory management and reduced costs to enhanced operational efficiency and supply chain resilience, the benefits of asset tracking are far-reaching and undeniable.

The future of supply chain management in Australia is undoubtedly being shaped by the continued advancements in asset tracking technologies. As businesses embrace these innovations, they will be better equipped to stay ahead of the curve, adapt to changing market conditions, and maintain a competitive advantage in the ever-evolving business landscape.

The revolution in supply chain management in Australia is truly exhilarating! With the power of asset tracking in telematics, Australian companies are now able to completely transform their practices and take their efficiency and productivity to new heights. This cutting-edge technology allows them to track their assets, whether it's vehicles, equipment or inventory, in real-time. Imagine the possibilities this opens up for seamless logistics and supply chain operations! By harnessing the power of asset tracking, Australian companies are positioning themselves for long-term success in the global marketplace. This transformative change is reshaping the journey of supply chain management in Australia, and asset tracking is the driving force behind this exciting revolution.